Inspection labels are color coded tags applied to images in the

Camera Images pane or the Filmstrip element in the operator

view. Each inspection label has a name, a configurable foreground

color, a predetermined background color, a value, a condition, and

a visibility. When an inspection label is applied to an image, the

name and value of the inspection label appear.

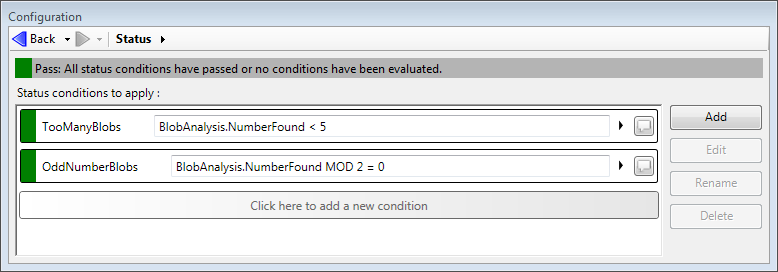

An inspection label's value is the result of an expression. For

example, if an inspection label has its value set to BlobAnalysis.NumberOfBlobsFound, then when the

inspection label appears, it displays the number of blobs found. An

expression label can be visible based on a condition that evaluates

to true or false, such as BlobAnalysis.NumberOfBlobsFound < 5. When

an inspection label's condition is true, the inspection label is

applied to the image. An inspection label's visibility determines

whether the inspection label will be visible on the images in the

Camera Images pane (design-time), the Filmstrip element in

the operator view (runtime), or both.

By default, there is an automatically added label for each

condition in the default

Status step in the main flowchart.

There are 3 categories of inspection labels: data, pass, and

fail. By default, these are set to a background color of gray,

green, and red, respectively. The data inspection labels display

some information, such as a time stamp or loop count. A pass

inspection label displays when an image passes its status step

conditions and a fail inspection label displays when an image fails

its status step conditions. Typically there will only be a single

pass inspection label, but several fail inspection labels, one for

every status condition that fails. The inspection labels can be

quickly identified by their color (for example, green for pass and

red for fail).

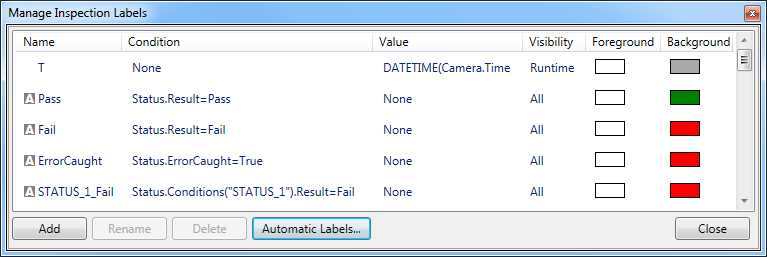

By default, a project starts with 4 inspection labels: T, Pass,

Fail, and ErrorCaught. A T label displays a gray timestamp, Pass

and Fail labels are discussed above, and an ErrorCaught label

signifies that the

Status step caught an error from either an

Error step or another source. For more information, see the

Catching and throwing exceptions subsection of the

Procedure for using the Status step and Error step section in

Chapter 23: Flow control steps.

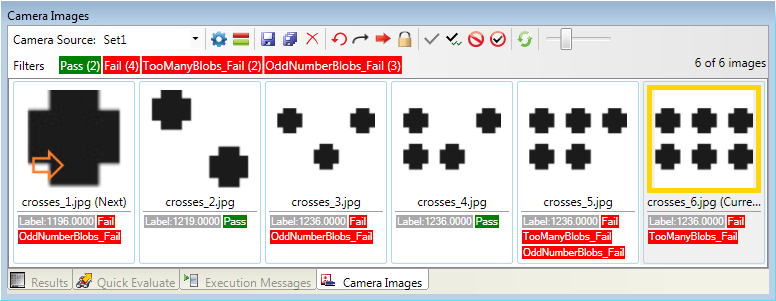

The following example shows a

Camera Images pane with images and several inspection

labels. The gray data inspection label is on all images and

displays the size of the first blob found. The red inspection label

called OddNumberBlobs_Fail is on the images that failed because of

an odd number of blobs. The red inspection label called

TooManyBlobs_Fail is on the images that failed because they have 5

or more blobs (note that after the inspection label name, the

number of blobs in the image appears). The global inspection label

called Fail is on the images that have one or more fail inspection

labels. The green inspection label called Pass is on the images

that passed all conditions in the

Status step.

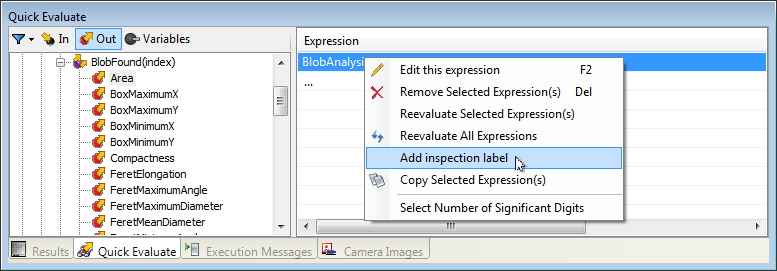

To edit inspection labels, use the Manage Inspection Labels

dialog, accessible from the Project menu or the toolbar

of the

Camera Images pane. You can also create new inspection

labels from this dialog.

Edit an inspection label by selecting it in the dialog and

clicking on the item to edit. Regardless of the category of

inspection label, the default foreground color, used for the font,

is white, and the visibility, used to determine where the

inspection label is visible, is set to Both. Typically, you will

add a condition for a data inspection label, and/or a value for a

fail inspection label. You can also set the background color to

create meaningful color-coded categories of inspection labels.

When adding an inspection label using the Manage Inspection Labels

dialog, the default background color is gray, and the Value and

Condition fields are empty. You must fill these fields manually,

usually by copying and pasting from the

Advanced editor of the

Configuration pane of another step.

In the figure below, you see the Manage Inspection Labels

dialog with the default inspection labels and the user-defined

inspection labels. Note that when the Condition field is empty, the

inspection label is always visible, but will still only appear in

the locations specified in the Visibility field.

You can click on the Automatic Labels... button

to have

Status steps that are not part of a

recipe create inspection labels automatically. You can see

which labels have been added automatically by the symbol added to

the left of their name.