BeadInspection step overview

A bead can be generally defined as a strip of malleable material, such as glue or lead. In many industries, such as manufacturing, beads can be used to, for example, bond objects together. In the following example, 2 beads of white glue (one open, one closed) have been applied to a mechanical part, and require inspection.

Using the BeadInspection step, you can inspect beads according to predefined specifications. For example, you can verify that a bead occurs at a required position, that its width falls within a certain range, that it does not have any missing sections (gaps), or that its gaps do not exceed a specified size.

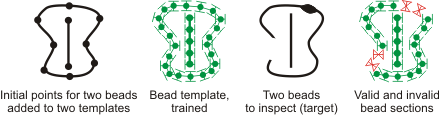

Beads are inspected with a template, which represents a reusable model of a valid bead. To create a template, you use a training image to interactively set the initial points that represent the sections in which a bead is expected. The template is then trained, using these points and an image, to calculate all the points (trained points) required to validate the bead. Once the template is trained, it can be used to inspect and validate beads in the target image.

If required, you can add multiple templates. Beads can be open or closed, and can have any shape.

The BeadInspection step allows you to choose from among many annotations, after validation or during the training phase, such as drawing all of the bead sections that failed due to an insufficient width. After validation, you can ascertain the pass/fail status of the bead or of each bead point, according to the specifications of the template. You can also retrieve measurements, such as width and position values.

If your parts move at runtime, you can use another step, such as the ModelFinder step, to reposition the template based on the found position of the bead to validate.