Matrox Design Assistant can communicate with industrial robot

controllers to offer an integrated machine vision solution. Matrox

Design Assistant has 3 Robot steps to interface

with your robot controller, RobotWriter

step, RobotWait

step, and RobotParameters

step.

|

Robot controller brand

|

Supported robot controller models

|

|

ABB

|

IRC5

|

|

Epson

|

RC420+/RC520+

|

|

Fanuc

|

LRMate200iC/LRMate200iD

|

|

KUKA

|

KR C2

|

|

Staubli

|

CS8/CS8C HP/CS9

|

Matrox Design Assistant communicates to the robot controller

which will then move the robot arm to the requested position. A

given robot contoller typically supports many different robot arm

models.

Programming

robot controllers

Programming

robot controllers

Before running any flowchart, you need to install binaries on

your robot controller, which allow you to use the specialized

commands to interface with Matrox Design Assistant. The commands

are specific to the brand of robot controller you have. For full

documentation of how to install the binaries on your robot

contoller, and an explanation of the Matrox commands to include in

your robot controller code, see Matrox Robot-side Communication

API. This documentation, along with the installation files and demo

code are all found on your computer at Program Files\Matrox

Imaging\MIL\Config\Robots.

Adding and configuring

robot controllers

Adding and configuring

robot controllers

Once a robot controller is connected to your network, you must

add and configure it in Matrox Design Assistant. You can add robot

controllers using the Robots page of the

Platform Configuration dialog. From here you can add,

rename, configure, or delete a robot controller. When configuring a

robot controller, you must specify its type and IP address.

When deploying a project, the connection between Matrox Design

Assistant and the robot controller closes. A new connection needs

to be made to the deployed (runtime) project. You should restart

the program in the robot controller so it can wait to re-establish

a connection with the deployed project.

Sample robot

flowchart

Sample robot

flowchart

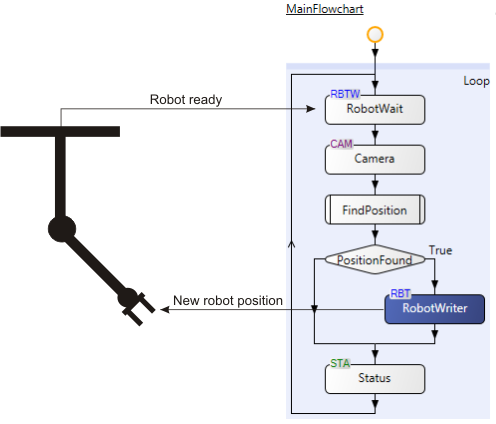

Using a robot controller with Matrox Design Assistant would

typically have a flowchart with a RobotWait step

near or at the top of the main flowchart loop, usually above a

Camera step. The RobotWait step

would pause the flowchart until it receives a request from the

robot controller. Program control will then return to the

flowchart, which would typically grab an image, process it, locate

an object or otherwise determine a position for the robot to move

to, and then send that position back to the robot controller

through a RobotWriter

step. The loop would then complete and return to the top, where the

RobotWait step

will pause until it receives the next request from the robot

controller.

The following flowchart demonstrates the general use case, with

the FindPosition subflowchart being all the steps that process the

image to locate where the robot should move to.

Position data is sent using the following 6 values: X, Y, Z, Pitch, Roll, and Yaw. In addition, for more

advanced applications involving multiple object/part types or

applications where multiple occurrences of objects might be present

in the field of view, you can use the ObjectId value to inform the

robot controller. For more advanced applications requiring

transferring data between a robot controller and Matrox Design

Assistant, you can use the Opcode value to inform the

robot controller about different operations.

Alternative

uses for the 8 values of the RobotWriter and RobotParameters

steps

Alternative

uses for the 8 values of the RobotWriter and RobotParameters

steps

The RobotWriter

step and RobotParameters

step send data to and receive data from the robot controller,

respectively. The data they transmit are named in Matrox Design

Assistant as the following 8 values: X, Y, Z, Pitch, Roll, Yaw, Opcode, and ObjectId. These values are

typically used to send position data, but can be repurposed. If you

use these values for an alternative purpose, you must ensure that

your robot controller code is modified accordingly.

Orientation

conventions

Orientation

conventions

If you require changing a project to a different type of robot

controller, note that the rotation axis name (roll, pitch, and yaw)

represents different rotations about positional axes, and are

represented differently on the robot controllers of various robot

manufacturers.

|

Robot controller brand

|

Convention

|

Rotation axis name

|

|

Roll

|

Pitch

|

Yaw

|

|

Fanuc

|

Rotation about positional axis

|

Z-axis

|

Y-axis

|

X-axis

|

|

Robot notation

|

R

|

P

|

W

|

|

ABB

|

Rotation about positional axis

|

Z-axis

|

Y-axis

|

X-axis

|

|

Robot notation

|

The orientation is converted by the robot controller to a

quaternion.

|

|

Epson

|

Rotation about positional axis

|

X-axis

|

Y-axis

|

Z-axis

|

|

Robot notation

|

W

|

V

|

U

|

|

KUKA

|

Rotation about positional axis

|

X-axis

|

Y-axis

|

Z-axis

|

|

Robot notation

|

C

|

B

|

A

|