Modbus steps overview

The Modbus steps allow you to communicate information, using the Modbus communication protocol, between your runtime platform and other Modbus devices, such as a programmable logic controller (PLC), expansion I/O modules, or a robot controller. Modbus is an industrial communication standard for connecting devices together, and it defines a communication protocol that allows interaction between devices used in industrial automation processes. The information is received or transmitted through the runtime platform's 100 Mbit/1 Gbit Ethernet port, or serial port (COM port).

There are 3 Modbus protocol types that are supported in Matrox Design Assistant (if provided by the runtime platform hardware) and that Matrox Design Assistant can be Modbus master to:

-

Modbus TCP, which uses the 100 Mbit/1 Gbit Ethernet port.

-

Modbus RTU, which uses the serial port.

-

Modbus ASCII, which also uses the serial port.

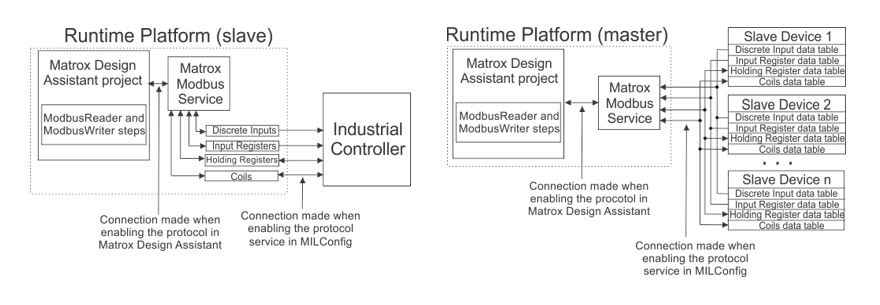

On the runtime platform, enable and configure Modbus communication using the MILConfig utility. You can configure your runtime platform as either a slave device or a master device. Typically, the runtime platform is configured as a slave device, but when communicating with some external I/O modules and robot controllers that are themselves slave devices, it is necessary to configure the runtime platform as a master device. If Modbus is already enabled in the MILConfig utility communication page, you can also use the Matrox Design Assistant portal page to configure this protocol. For more information see Portal pages for monitoring communication.

Once communication has been configured in the MILConfig utility, you can communicate with a PLC (or other device) using the ModbusWriter step and the ModbusReader step. The ModbusWriter step allows you write to Modbus data tables, and the ModbusReader step allows you read from Modbus data tables.